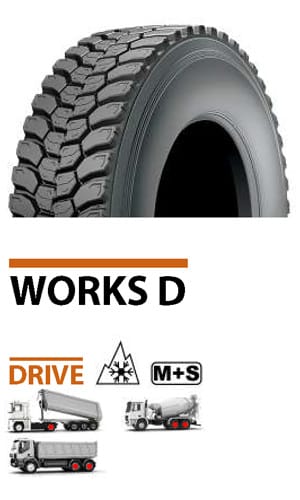

RECAMIC ®

The trusted, cost-efficient and sustainable Recamic retreads.

The performance and overall quality of a Recamic tread is comparable to that of the of newly produced, premium tires. The special formula of the Recamic tread uses rubber compounds developed and manufactured by Michelin. Recamic retreads have an optimized mileage return and lower your TCO (Total Cost of Ownership).A preformed tread with the final profile is mounted on the pre-inspected carcass. Vulcanization in an autoclave, heated to approximately 115 °C for about three hours, transforms the product into a very strong whole. This form of production offers many advantages, including comparable performance to that of new premium tires and a lower cost per kilometer. In addition, tire retreading reduces the consumption of raw materials, resulting in less residual waste.

Our production process

Learn more about our production process below. Our factories work with best-in-class industry standards that enable the production of safe and performing tyres. Our processes have been secured and perfected through decades of experience.

Our senior expers thoroughly inspect the tire and go through a critical assessment.

We then conduct a laser shearing interferometry that scans, detects, and locates internal damges.

Our buffing machine subsequently removes excess remaining rubber from the casing and restores it to its ideal dimensions

After the buffing, the skiving process allows any superficial damages to the casing to be carefully cleaned out.

Then, a Recamic pre-cured tread is applied to the casing with a layer of uncured rubber, whicn ensures a permanent bond between them after the curing process.

Finally, a curing/vulcanising process permanently bonds the Recamic tread to the cleaned and repaired casing. The last step is followed by a finalinspection.

Our mission is to transform the linear tyre industry into a circular one. To make an impact on the world, one tyre at the time.

Frequently Asked Questions

Here is a collection of questions that our clients frequently ask us.

Other products

See what we specialize in and how we do it

MARANGONI®

We are the exclusive Benelux Ringtread partner. We offer a circular, double-contoured, and spliceless profile. Ringtread tyres can match or even exceed the performance and reliability of new high-quality tyres, making them a great choice.

UBO®

On December 31, 2024, we permanently closed our tire retreading factory, UBO, nearly 88 years after its founding. The bankruptcy was caused by high energy costs, difficulty in finding technical staff, and the dumping of cheap truck tires from the Far East, which disrupted the local market.